Understand the Various Benefits of Mixed Model PCB Assembly

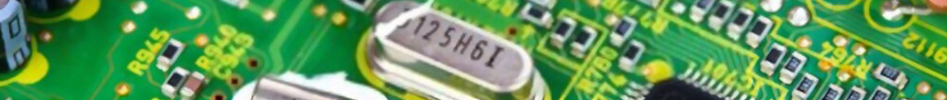

Mixed model PCB assembly is a type of assembly that uses a mix of surface-mount and through-hole components on a single board. In other words, it involves a mix of automatic and manual processes. This type of assembly is often used for products that require a mix of high-density and high-reliability components. Mixed model PCBs can be more challenging to assemble than traditional PCBs, but the benefits often justify the extra cost and effort. There are many reasons why you need to consider mixed model PCB assembly for your project. As the electronics industry rapidly evolves, more manufacturers are looking for advanced assembly solutions that can keep up with the demand. In order to stay competitive, many are turning to mix model PCB assembly. It is fast, accurate, and allows for a higher degree of customization. Here are the other few reasons why you should go for the process of assembling PCBs with a mix of different component types.

Reasons Why You Should Use Mixed Model PCB Assembly in Your Project

There are many advantages of employing the technique for your next PCB project. Here are just a few of the top advantages:

- Increased Reliability and Durability: PCBs that include a mix of technologies are often more reliable and durable than those that rely on a single technology. It is because the mixed model PCB assembly process leads to boards that have a more diverse set of electrical properties. For example, a board with both SMT and PTH components is more resistant to vibration and thermal cycling than a board with only SMT components.

- Fast Turn Around: With mixed model, you can expect a fast turnaround time without sacrificing quality or reliability. By allowing you to have a single assembly line for your PCBs, you can greatly reduce the time it takes to get your products to market.

- Less Human Labor: This model requires less manpower, which can lead to significant cost savings for businesses. In this model PCB assembly line, the various assembly tasks are performed by different machines. This allows for a higher degree of automation, which reduces the need for human workers. In addition, it is less likely to cause errors, which can lead to low scrap rates.

- Enhanced Stress Tolerance: Mixed model PCB assembly can lead to increased stress tolerance in electronic devices. This type of assembly involves placing components of different sizes and shapes on a circuit board, which can help to distribute stress more evenly across the board. This can lead to improved performance, especially in devices that are subject to high levels of stress.

Applications of Mixed Model PCB Assembly

Mixed model PCB assembly is a process that can be used to assemble circuit boards with various component sizes and densities. This type of assembly is often used in high-density applications, such as devices that require a high level of functionality in a small form factor. The following are a few application areas of PCBs that are assembled using mix model technology.

- Server Boards

- Video Processing Units

- Communication Hardware

- Sensor Boards

- Timer-based water sprinklers

- Air conditioners

- LED Lighting Products

- Tablets

- Wearable devices

- Industrial control systems

- Infrared Remote-controlled Televisions

Needless to say, mixed model PCBs assembly are in demand and will continue to drive innovations. Thanks to its ability to support surface-mount (SMT) and pin-through-hole (PTH) components on the same board, along with offering greater design flexibility. They also allow for a more efficient manufacturing process, as both SMT and PTH components can be placed and soldered at the same time. In addition, mixed model PCBs are easier to troubleshoot and repair, as they provide greater access to individual components. Also, as they use less material than traditional PTH boards, they are also more environmentally friendly. For all these reasons, mixed model PCBs are becoming increasingly popular with electronics manufacturers.

Being said this, it is extremely important to work with a reputable PCB manufacturer like Accelerated Assemblies to get your PCB assembly employing mixed model technique. There are many fly-by-night operations that will take your money and give you subpar products. You don't want to end up with a board that doesn't work! There are a few things you can do to ensure you're working with a reputable manufacturer. First, check to see if they are ISO 9001 certified. This certification means that the company has met strict quality standards. Second, ask for references from other companies that have used their services. A good manufacturer will be happy to provide you with a list of happy customers. Finally, be sure to get a quote from the manufacturer before you commit to working with them. This will allow you to compare prices and make sure you're getting a good deal.